How long do surface treatments take?

Over time, road surfaces get worn down by both traffic and the weather. When roads fall below a certain standard, it is necessary to carry out road maintenance, whereby surface treatments are applied. Factors that are considered when deciding what form of road maintenance to use include the current condition, how busy the route is, and which treatment will be most efficient in terms of costs, time and disruption to travelers.

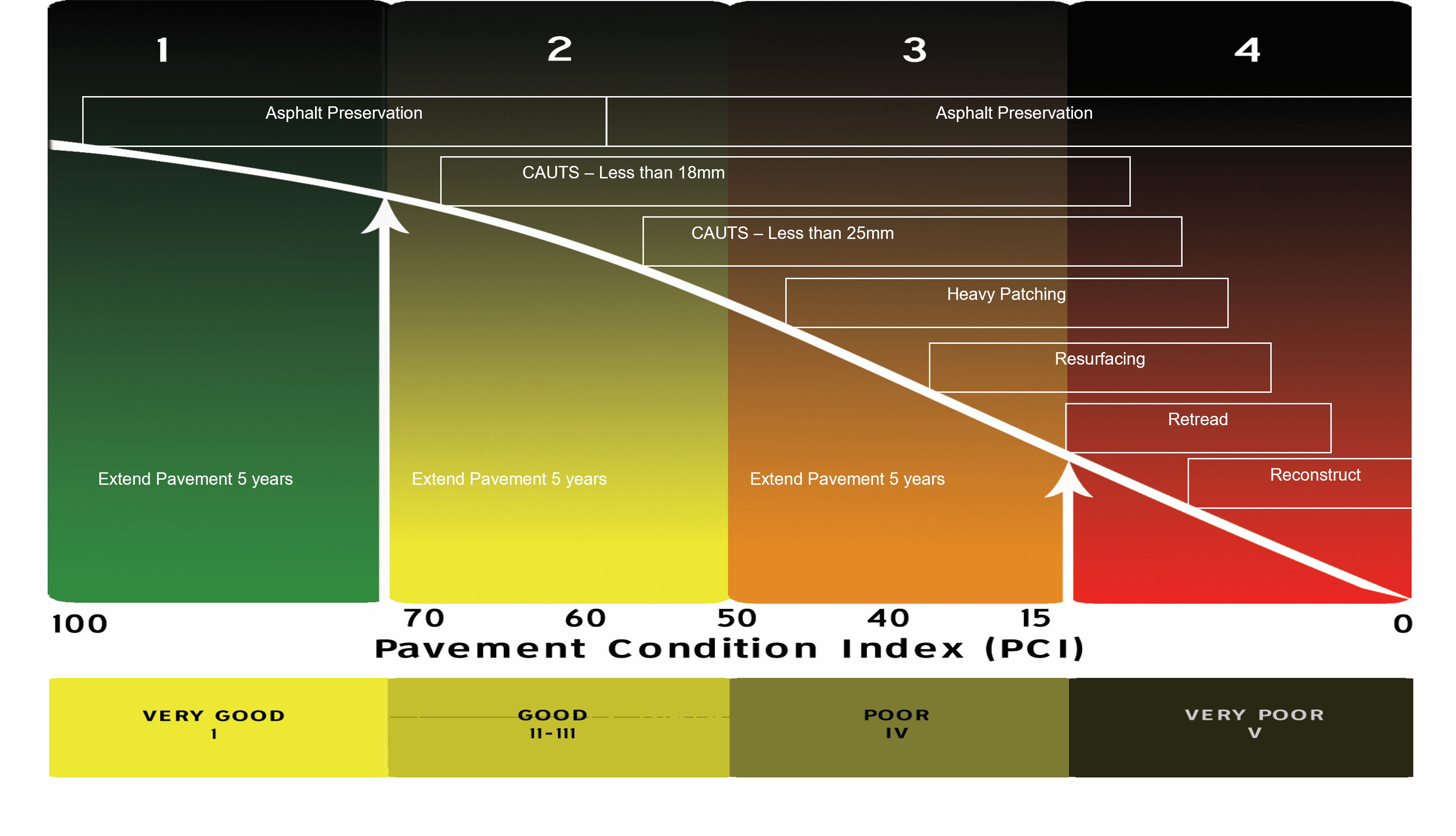

Types of treatments used include asphalt preservation, surface dressing based techniques, microasphalt based techniques and resurfacing. Resurfacing involves removing the existing surface and replacing it with new asphalt. Road resurfacing is usually the last resort (especially on busy highways) as it can be extensive, very costly and extremely time-consuming.

The time it takes to resurface a road surface can vary greatly. It usually takes longer than surface treatments as it involves more extensive structural maintenance such as removing the worn-out road surface and replacing it. During this time, a diversion is put into place to allow for the work to be carried out.

Resurfacing involves clearing the area of pedestrians, vehicles and debris before removing some (or all) of the existing road surface. Once this part of the resurfacing process is complete, a bitumen spray coat is applied before the new surface is laid.

As asphalt needs to be installed in optimal conditions for it to be effective, resurfacing works may be delayed due to bad weather. This is especially common during the autumn and winter months, when rain and snow can be a constant in the weather forecast.

Once resurfaced asphalt is laid, it must be left to dry. This can take up to 24 hours depending on the weather conditions. Rainfall and extreme temperatures can prolong the drying period. Due to these factors, resurfacing can be a lengthy process.

Our solutions can be installed in a shorter timeframe than traditional resurfacing, meaning lower costs and minimal disruption.